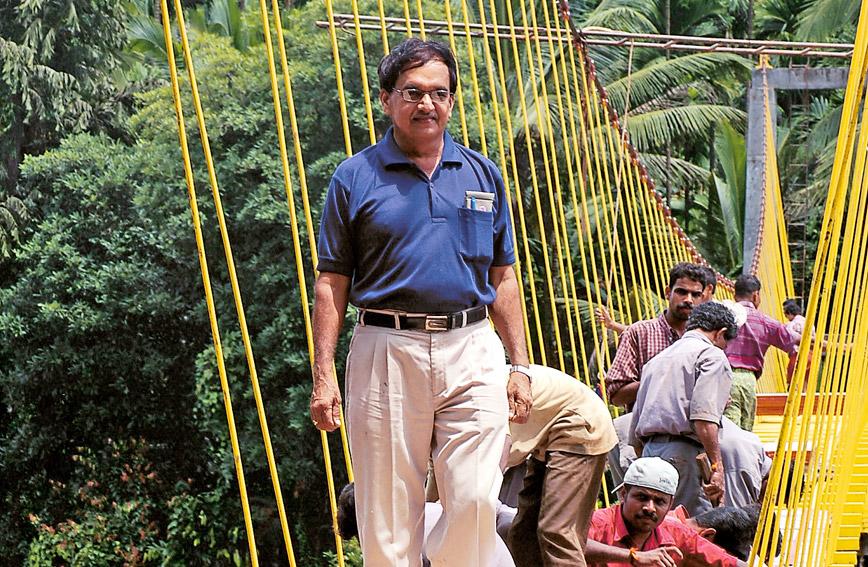

Girish Bharadwaj inspecting one of his bridges

Girish Bharadwaj

An engineer can transform lives. Girish Bharadwaj learnt that by sheer chance and stayed hooked. When he got his mechanical engineering degree as a young man he hoped to find a good job and settle down in a big city. Things didn't work out that way. Instead he had to set up a workshop in his village in Karnataka's Dakshina Kannada district.

One day a forest officer asked him to build a small hanging bridge in Kodagu district. Despite having no experience in building bridges, Bharadwaj took on the work and hasn't looked back since.

He saw for himself what a difference a bridge makes to the lives of people. Many villages in Karnataka and Kerala used to spend months in isolation because they were unable to cross rivers. It means the inconvenience of long detours and the loss of livelihoods. It is even difficult for families in such villages to get marriage proposals.

Bharadwaj's first low-cost suspension bridge was built in 1989. After that he has built many. He has found ways of bringing the cost of constructing a bridge down. Community labour is one of them.

His work as a grassroots engineer has got him a lot of appreciation from villagers whose lives he has changed. His bridges allow them to take their produce to the market, drop their children to school and so on. In 30 years, Bharadwaj and his team have worked untiringly to build over 120 bridges across the country.

Below is a 2007 cover story by Shree Padre from Civil Society's archives. Read on.

Ever since they can remember, most of the villagers of Delampady in Kerala’s Kasaragod district have lived a dual existence: as part of the mainland for six months and as a fragile and worried river island for the rest of the year when the surging waters of the Payaswini cut them off during the monsoon.

Now, a simple and sturdy suspension foot bridge has put an end to such uncertainty. It spans 105 metres and makes it easy for villagers to go to work and school, transfer provisions or get a sick person to hospital.

Constructed in four months, the bridge has cost just Rs 21.5 lakhs. Villagers can’t believe that it has taken so little to end five decades of isolation.

The villagers’ hero today is Girish Bhardawaj, 57, a mechnical engineer from Sullia, in the Dakshina Kannada district of Karnataka.

Girish is not new to such adulation. He has been building bridges for the past 18 years. There are 66 that he has to his credit. The bridges are mostly in Karnataka and Kerala, but there are a few in other southern states as well.

In his career as a grassroots engineer, Girish has helped at least 200,000 hapless villagers cross rivers safely. For them he is a saviour.

In the initial years, local civic bodies used to reject the idea of a suspension bridge. “It is only a temporary structure the Army builds in emergencies,” they would say dismissively. “The Army dismantles such bridges after their purpose is served.”

Now, fully convinced, they call for tenders for constructing suspension bridges. In Karnataka, it is only Girish who builds them.

With the success of each bridge, the word spreads. There are now eight bridges across the Payaswini. Nine bridges have been erected over the Chandragiri, which the Payaswini joins. The bridge completed at Delampady is the fourth in that panchayat area, which is plagued by communication hardships.

“This is the culmination of a long struggle,” says MC Narayanan Nayar, one of the villagers who will benefit from the new bridge at Delampady.

Purushoththama, a farmer, is also relieved: “My work demands that I have to cross this river twice daily. My bread is on the other side.”

“The inner bank becomes an island for half the year. It has meant crossing the river in country-boats and walking four kilometres to catch a bus,” he says. “For bringing home provisions, transporting patients and so on one would have to hire a jeep. A single trip by jeep costs Rs 150, which is a steep price for us villagers. It would also mean doing 13 km on a circuitous road.”

A bridge makes life easier for everyone

A bridge makes life easier for everyone

Like Purushoththama, there are half a dozen other locals who have voluntarily worked on the suspension bridge because of the difference it will make to their lives.

Involving local people is an integral part of Girish’s bridge-building. So, he normally camps at the construction site with his crew of 15 or so, eating, sleeping and solving technical problems on the spot.

Being around facilitates close supervision. He can see for himself that technical specifications are being met. But even more than the hands-on engineering, it is the spirit that really matters. Each bridge is an expression of bonding. “We bridge the gap between places, people and hearts,” says Girish.

His father’s son Girish belongs to a farming family from Aramboor, near Sullia. He wanted to become an engineer because his father was one. However, Balekkala Krishna Bhat, his father, would call an engineering degree a ‘begging bowl.’ Having served the Central Public Works Department (CPWD) at various places, he was fed up with the system. He saw little point in his son being an engineer.

Girish’s mother had to intervene to persuade his father to send him to an engineering college. “The college fees were Rs 600 a year and hostel fees Rs 90 a month. It was a lot of money for us,” recalls Girish.

Workers run many risks while putting up a bridge

Workers run many risks while putting up a bridge

He studied mechanical engineering at PES College of Engineering in Mandya and got a first class. Girish’s father wanted him to stay home and serve the local rural community. When Girish sought his blessings before going to Bangalore for an interview for a job, he remarked, “Go, enjoy Bangalore and come back. I will keep praying that you shouldn’t get the job.”

Girish went on trying. Jobs were difficult to find at that time. One day he had gone to the office of the local transporter with his father. An old pump-set was kept there. The agent said it was being sent to Puttur for repairs. While returning home, Girish’s father said to him: “When you, an engineer, are here, why should our farmers have to send their pump-sets elsewhere for repair? You start a small workshop. Later on it will grow. Kirloskar too came up the same way.”

For the youngster who was dreaming of a city job, this was a great disappointment. His father was asking a qualified engineer to perform the role of a mechanic. “Yet on second thoughts,” Girish recalls, “I bowed to my father’s wishes and wore the blue overalls of a mechanic.” His small workshop in Sullia opened in 1975. Being the only workshop in the town, he was asked to do different types of jobs from machinery erection to general fabrication.

For all his aspirations of employment in a big city, Girish did not mind working with his hands. Indeed, with time he found that he really enjoyed it. He took up local assignments with great zest and did not shy away from manual work.

The stepping stone In 1989 came a turning point. A Range Forest Officer approached him to build a small hanging bridge at Nisargadhama, in Karnataka’s Kodagu district.

Girish Bhardawaj inspecting one of his bridges

Girish Bhardawaj inspecting one of his bridges

At that time Girish didn’t know anything about building bridges. But he took on the work. “I didn’t have any design, nor did I have calculations. Yet, the bridge continues to serve,” he says laughing heartily.

“I never dreamt at that time that I would end up constructing bridges throughout my life like this.”

Nevertheless, that is what destiny had decreed. A few years after the first bridge, villagers from his native village of Aramboor requested him to construct a bridge across the Payaswini. They would not take his pleas of lack of experience seriously because he had already put up a bridge. Girish had to yield. As it was his native village, he took only the cost of materials.

When two days were left for the inauguration, a village elder, Kittanna Rai, admonished him, “Why have you put such a narrow rope? Won’t people fall while crossing?”

“This question haunted me. When I closed my eyes, I would see the picture of a falling bridge,” says Girish. He couldn’t sleep that night.

So worried was he that at midnight, he rushed to his workshop to check whether anything had gone wrong with his calculations. No, Girish’s calculations were correct. The rope was narrow, but the bridge was secure. Finally, the bridge was inaugurated with much fanfare.

After Aramboor, there was no turning back. He consulted many books. The principal of a local engineering college was of much help. Now, when it comes to making low-cost bridges in difficult terrain, there is perhaps no one in India equal to Girish. Yet, he takes each new bridge as seriously as he did the one at Aramboor.

At all the crucial stages of construction he invariably remains with his crew. The mood is wholesome and productive. During an entire day spent with him, we didn’t notice any indication of tension, anger, complacency or arrogance in his interactions.

“See, it’s a big responsibility. I can sit pretty at home and leave my boys to do the work. But that makes me tense. If I am at the site, I can caution them, ensure quality and safety both for the bridge that is being built and my boys.”

Initially he used big trees as pylons if they were available at the right place. Concrete pylons are now preferred because of their assured long life. Multi-strand steel ropes pass through rollers fixed above the pylon. These are tied to specially built anchors on both sides. Rods suspended from the rope at fixed intervals – from these suspenders has come the name “suspension foot bridge” – are connected to transoms. A lengthy floor element is later fitted connecting all these transoms.

“Before doing this, our boys cross the bridge by hanging on to these transoms like circus performers,” says Girish.

The ferro-cement decks inside a steel frame are finally fitted onto the floor element. On both sides of the bridge, PVC coated chain-link fencing is erected till waist-level. If girders are used in place of chain- link fencing, it reduces vibration considerably. Though slightly expensive, the girder uniformly distributes the load.

Over the years, the bridges have seen many innovations. Earlier, in place of ferro-cement decks, wooden ones were used. This time he has opted for a tapering circular column for the pylon. The earlier columns were rectangular. It required four columns for a pylon on one side. With interconnecting beams that design was costlier. Now there are only two columns. For the next bridge, he intends to have a single pylon. This was an idea he got on the Internet where he saw how two ropes can be hung from the same pylon. Girish has already incorporated this new design for three proposals he has submitted.

In the present bridge he has provided extra holes on both edges of the transoms. This is for easier fitting of stiffening girders, if required sometime in future. If the holes are not there, to get them drilled later in certain villages is expensive. Taking the future into account in the local community’s interest is another aspect of Girish’s mission.

Are the bridges completely safe for two-wheelers? You are okay if you ride carefully. Braking suddenly can cause problems for the bridge. An extra longitudinal beam has been incorporated in the floor to make the bridges safer, but it is necessary to be cautious.

Cattle too can use the bridge, but the dung they leave behind can be corrosive if it isn’t washed off periodically.

The bridges bear a load of 400 kg per square metre. The figure varies. One being constructed at Kuntaru near Sullia is 1.2 metres wide. That means every running metre can take 480 kg. The point to remember is that a hanging bridge is a low-cost alternative that is easy to build. It is not meant to do heavy duty.

Bridging people Girish’s people-based approach attracts considerable local support. People are happy to give their labour free of cost. The Aramboor bridge was built entirely with people’s participation.

“At Bavikere, near Kasaragod, people on either side of the river were not on good terms. But by the time our bridge was complete, their differences had melted,” remembers Girish. “At the inauguration, one side brought benches for people to sit on and the other side brought homemade sweets.”

A great deal of workmanship goes into the making of a bridge

A great deal of workmanship goes into the making of a bridge

At Baluvanthadka, in Kasaragod district of Kerala, where a 143 metre bridge was built eight years ago at a cost of Rs 15 lakh, almost everybody seems to know Girish intimately. “We don’t have words to describe his contribution to connecting these cursed hamlets,” says Raveendra Nayak stopping his motorcycle on the bridge.

Once the bridge was ready, 30 two-wheelers were bought by the villagers of Baluvanthadka. The bridge allows them to take their produce to the market, drop their children to school and so on. Earlier, on many occasions, villagers who had gone to Kasaragod, just 30 km away, had to spend the night away from home because boats wouldn’t ply after 5.30 pm. A boatman would charge Rs 10 per person. The result was that only 10 or 15 people would venture out of the village on most days. Now, on an average, 200 people cross the bridge every day.

During its construction, despite the panchayats contributing to the bridge, there was a shortage of Rs 60,000. Girish suggested that if more villagers gave their labour, the money would not be needed.

Recalls BS Thimmappa, a local farmer who agreed to camp with Girish and his crew in a tent at the site, “It was like a festival. Every day, 60 to 100 people assembled in the morning and worked until dusk. This went on continuously for two months.”

That apart, at the final stage, the villagers again fell short of Rs 90,000. They never managed to pay up and Girish waived the amount saying, “Oh, forget it. It was just my profit. Instead I have got the affection of so many people.” The bonds between the villagers and Girish are very strong. They invite him for all the functions at Baluvanthadka.

Land values have gone up at Baluvanthadka. Prices of essential commodities have come down. Since the village no longer has the black mark of being inaccessible, marriage proposals have begun coming in.

During construction, civil works like pylon construction, digging the land for building the anchor etc are done in the first phase. After the concrete is cured, work on the bridge continues without stopping. Totally it takes about four months to put up a bridge.

It is teamwork that puts a good bridge in place

It is teamwork that puts a good bridge in place

Most of the staff who made the initial bridges 18 years ago still work with Girish. Those who have grown too old for the rigours of bridge-building are employed at his fabrication unit, Ayas Shilpa, which is Sanskrit for structures of steel. But what about you, we ask Girish. “I never get old. My body might have grown old, but the spirit is the same”, he smiles. “Even now, if need be, I climb up the pylon.”

Today those who see Girish’s workaholic nature, his hectic schedule and frequent travel wouldn’t believe that he had a heart attack seven years ago. Later, he underwent angioplasty. Immediately after the attack, while he was being treated at a hospital in Puttur, he was busy designing a bridge for a Hyderabad builder. Till a bridge is completed, he floats between both banks of the river at least six to eight times a day in a unique boat.

There are no moving parts in Girish’s bridges. The only maintenance required is greasing and painting against rusting. It is enough if this is done at least once in two years. Girish believes that the bridges can last for a century if there is proper maintenance. The ropes might require replacement in 50 years if no maintenance is done. However, by the coast a hanging bridge’s life would be shorter.

If the span is big, a suspension bridge is cheaper than a concrete footbridge. A suspension bridge can also be dismantled and erected again elsewhere. This, says Girish, can save 60 to 65 per cent of the total cost. The rest of the expenditure is on civil works. A bridge has been shifted from Pallangodu to Munhampara. The reason was that a motorable concrete bridge came to be constructed at Panathoor. The hanging bridge was no longer required.

Is it possible to build motorable suspension bridges? “Yes, but again, if it’s a small span, it is better to go for concrete bridges,” says Girish.

An estate owner from near Ooty wants him to build a 50-metre-long hanging bridge on which his jeep can pass. “I strongly advised him against it because a concrete bridge would be a better choice and relatively cheaper; but the owner seems to be adamant about a hanging bridge,” he says.

Right now he has six bridges in the pipeline and is planning a 1.2 km long one in Tamil Nadu. It will serve 9,000 people. “It is possible. But depending on the availability of the length of the multi-strand steel rope, we might have to go for four or five spans in between,” says Girish.

A suspension bridge looks delicate but is very sturdy

A suspension bridge looks delicate but is very sturdy

Since there is no other agency in Karnataka and neighbouring states which regularly builds hanging bridges, Girish has to yield to pressures now and then. It is under such pressure that he started taking government contracts for bridges. Such contract work is not without delays in payments and unforeseen losses. “It is quite an irritating experience. You have to yield if you are to complete the work. I sometimes feeling like dumping the contract, but seeing how unhappy people without a bridge are, I tell myself that at least for their sake I should tolerate this unpleasantness.”

Bridges unlimited The ground reality is that there are hundreds and thousands of sites where a hanging bridge is required to help cut-off communities. Girish says: “The Dakshina Kannada Zilla Panchayat has received applications for susepnsion bridges at 41 sites from three taluks alone – Puttur, Buntwal and Belthangadi. These are community demands. There must be more sites where other communities need bridges.”

Hundreds of bridges are proposed, but never taken up for want of funds. Girish points out that voluntary labour by local people who benefit from the bridge is one way of completeing these projects.

But is there any way of speeding up the construction of bridges? Girish believes it is possible by training efficient teams. “I was telling the secretary of a Member of Parliament from Madhya Pradesh to give me a dedicated engineer and a dozen hard- working boys. I will guide them for two or three bridges. Thereafter, they can do it on their own.”

About 30 per cent of the cost of a bridge is labour. Even unskilled labour will do. If communities organise themselves and provide voluntary labour, points out Girish, they can save this amount.

Girish always has a mix of trained staff and freshers. In this way some new people are trained each time. “This is work anybody can learn,” he says.

People’s participation is important for one more reason. Labour is becoming scarce. “Earlier we had any number of people willing to be employed as workers on a project. Now they are hard to find even if we advertise.”

People’s participation Out of the 66 bridges built so far, 24 were made in Kerala. People’s planning has been a blessing in Kerala with the three-tiered panchayats being able to sanction money for such development works. This is one reason why so many bridges have come up in Kerala. “The spirit of people’s participation is also far more there when compared to Karnataka,” Girish says.

Some years ago, Instruct, a Bangalore-based training organisation invited Girish to conduct classes for Bhutanese engineers. While he was explaining the suspension bridge design, he noticed that the trainees looked bored. On asking, Girish learnt that they knew the design very well, but faced problems with erection. The method followed by them was very cumbersome. They were so impressed by Girish’s work that after the workshop was over they came to his hometown, studied the bridges and went back filled with confidence.

As we were talking, a message came that the new footbridge was almost ready. We were the chosen ones to inaugurate it. Entire families came out to welcome their new neighbour, the hanging bridge, at the impromptu inauguration.

As the sun began sinking, Girish walked on the footbridge with his never fading smile. “Looking back, what do you now think about this? If you hadn’t heeded your father’s advice, what would you have been?” we ask Girish.

“Oh, I would have been lost somewhere,” he said. “I would have been a cog in the machine. I get a lot of happiness from this work. In between bridge projects, my general fabrication work continues to sustain me and my staff.” Girish then recited from HW Longfellow, a poet who has inspired him greatly.

Lives of great men all remind us

We can make our lives sublime

And departing, leave behind us

Footprints on the sands of time.

Comments

-

Fellow - Oct. 9, 2019, 4:51 p.m.

Nice article